Exact Downhole Pressure Monitoring System

(EDPMS)

High-Temperature Pressure Monitoring

Able to go where no Pressure Gauge has gone before!

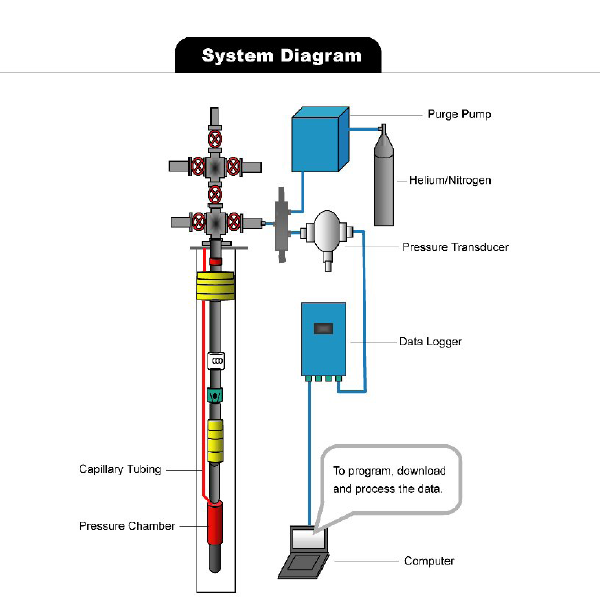

DataWise’s EDPMS high-temperature pressure monitoring system can handle the toughest well conditions. The unique design does not require any moving parts or electronics downhole. Down-hole pressure is transmitted to the surface via a column of inert gas contained within a capillary tube and is actually measured at the surface which allows unprecedented capabilities to evaluate system performance and re-calibrate or replace poorly functioning system components.

Operating Principle

Bottom-hole pressure (BHP) is communicated to the surface through a capillary tubing string where it is measured by a surface-located pressure transducer. Proprietary capillary tubing design and downhole pressure chambers ensure the system functions properly without the need to continuously pump gas into the system as in a “Bubble-tube” approach. When combined with DataWise’s Intelligent Data Logger, BHP is automatically calculated from the surface recorded system pressure accounting for changes in the gas column density and volume.

Long Life

Long Life

Because there are no electronics or moving parts downhole, the EDPMS systems will last for the life of the well without worry of failure regardless of downhole temperature. This makes EDPMS perfect for all applications where conventional electronic and fibre optic gauges will only last a limited time

System Response

EDPMS BHP measurement compares favorably with calibrated downhole electronic pressure measurement. Because of the column of helium in the capillary tubing, there is a storage and lag effect on the pressure response. But comparison testing during PBU surveys verifies unless downhole shut-off valves are used, EDPMS transient data analysis yields comparable results.

Wellbore Specific Chamber Design

No “cookie-cutter” gauge carrier is required to be force-fit into your well completion! DPMS chambers are designed for each individual well. Wellbore space requirements are taken into account when sizing the chamber for your given well conditions and pressure range. Metallurgy for EDPMS chambers and capillary tubing is chosen based on your specific well environment.

Internal or External Sensing

EDPMS Chamber design allows for pressure sensing either to the inside of the tubing or to the casing annulus and is built based on your specific well application requirement. Because of this flexibility, the EDPMS can be installed permanently as a part of the completion string or cemented in place as part of the casing string.

Full-Bore Design

Because the chamber design for an EDPMS system starts with your standard tubing size for a given completion, EDPMS pressure chambers are always full-bore diameter. This feature also allows for running with internal components such as rod strings for artificial lift. The use of customer-supplied tubing also ensures proper threads will be supplied for a given system.

Pressure Rating

The chamber pressure rating is designed based on your well design pressure requirements. Capillary tubing burst pressure rating is >40,000 psi.

Customer Selectable Pressure Gauge Quality

The pressure transducer location on the surface, allows you to choose strain or quartz technology based on your reservoir monitoring requirements. The surface transducer location also allows you to change the transducer type, making the EDPMS more cost-effective.

Pressure Testable Chamber

The EDPMS system design allows for the complete downhole system to be tested on the rig floor prior to installation, including the capillary tubing and chamber connection.

Effortless Wellhead Isolation Compared to electronic gauge penetration through your wellhead, the EDMPS Integrated well design offers an exit valve which isolates the EDPMS downhole system at the wellhead.

Compared to electronic gauge penetration through your wellhead, the EDMPS Integrated well design offers an exit valve which isolates the EDPMS downhole system at the wellhead.

IDL “Intelligent Data Logger”

DataWise’s IDL offers all standard capabilities of most conventional data logging systems plus features designed specifically for EDPMS and its unique ability to collect BHP data. See the Intelligent Data Logger brochure for more detailed information.

Further Reading

Improved Accuracy of EDPMS Systems with a Near-Surface Wellbore Temperature Sensor |

Why Does EDPMS work at High Wellbore Deviation?

|